Automatic product classification system by using BARCODE

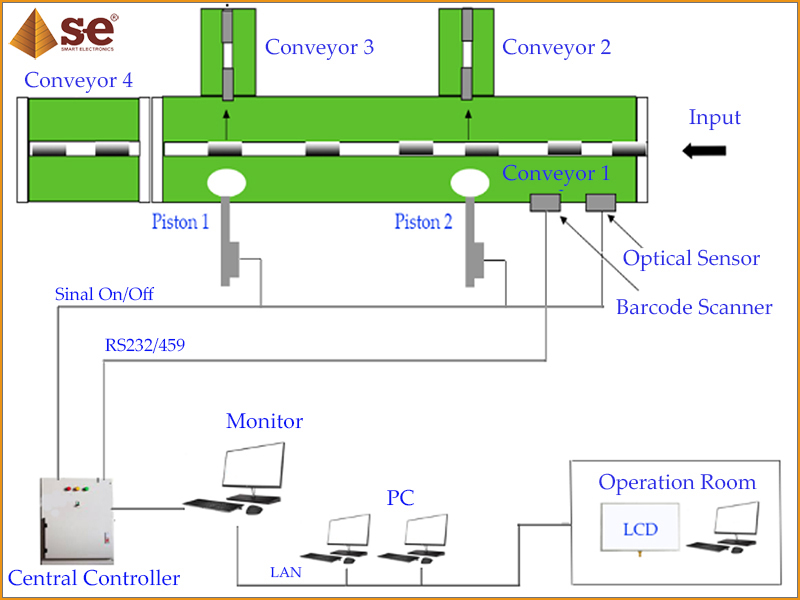

Operating principle:

- Some model barcode samples have been loaded into the system. These samples are used for comparison and determines whether the product is passed or not.

- When the product on the conveyor belt goes to the sensor system. If there is a Barcode code on the product that does not meet the standard, the system will detect and the piston will push the product across another conveyor, and produce an error sound for this incident.

- Incident information will be recorded on the server for reporting purposes.

Modes of operation:

- Scanning the barcode of the product at the end of the conveyor.

- Receiving defective barcode signal.

- Detecting a product box without barcode.

- Timing of piston control pushes the product through another line.

- Counting the number of defective products and classifying towards barcode.

- Displaying information on LCD screen.

- Playing warning sound.

- Transporting data to server to serve for reporting.

ភាសាខ្មែរ

ភាសាខ្មែរ Tiếng Việt

Tiếng Việt