Theory of the Andon system

- The ANDON system is a tool to detect abnormalities in the production process, then immediately notify by sound and image to the group of people who are in charge of the unusual area. The phrase ANDON is derived from the name of a Japanese bamboo and paper lantern.

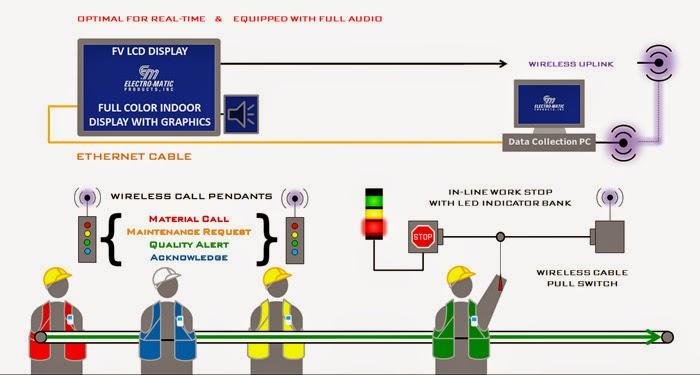

- The ANDON system has many forms: from warning to one location to alerting multiple lines and stages; from simple warning light / bell to complex tables.

- The common feature of all forms is the production warning system of real-time production status in the monitored area.

The ANDON system brings back values for factory

- The operating principle of the ANDON system is to allow employees or equipment to activate the production warning system when noticing abnormalities, sending notice of action to be taken immediately (repair, maintenance, material supply, …). Based on the signal the ANDON system sent, the production executive dispatched the appropriate person to assist.

Operation process of the ANDON system

- The ANDON system brings back many benefits for the factory in production and management. In production, the ANDON system ensures production safety for humans and extends the life expectancy of equipment. The ANDON system also prevents defective products from reaching customers, while avoiding the occurrence of mass errors on many products. In addition, the supporters know when there is a problem, they know exactly where to go and what problem to solve, saving time to troubleshoot.

- In management, the ANDON system firstly allows the production team to spend less time and less effort to track the machine to monitor the situation. Instead, they have more time to troubleshoot. Next, the production warning system indicates unreasonable places in the current production line. Overcoming the anomalies is an opportunity to reduce errors expressed through the frequency of stopping troubleshooting. Thanks to the updated use of equipment and the repair and maintenance process, the operator team can monitor the equipment and the repair personnel accurately. Finally, the warning system produces as a two-way communication program: when the indicator light turns green, the system is operating normally.

- On the contrary, there is some misunderstanding about the ability of the ANDON system.

- Firstly, the ANDON production warning system can report an error but cannot resolve the error itself.

- Secondly, the production warning system cannot remove the existing defects on the chain as well as on the product but that error must be fixed by humans. If not in subsequent operations, the production warning system continues to report the error and stop the line.

- Thirdly, although it is possible to report the fault or normal status of the line, the ANDON production warning system can not be considered as a communication tool between people and people. If workers and supervisors need to communicate with each other, they still need to communicate with each other directly.

- In short, the ANDON system is a part of the process of supporting quality control. The production warning system has an important function of informing when there are abnormalities arising, avoiding the occurrence of mass errors. Besides easy-to-read values such as quick fixes and reduced workloads of monitoring, information storage, and troubleshooting of unusual incidents. It will help existing chain improve significantly as well as keep long-term value for the system. Investing in the ANDON system is purely an investment that brings many benefits.

ភាសាខ្មែរ

ភាសាខ្មែរ Tiếng Việt

Tiếng Việt