Specifications:

- Information Display Board

- LCD Screen

- LED Screen

- PC

In order to meet the increasing demand in the Southeast Asian, mainly in manufacturing factories and industrial parks.

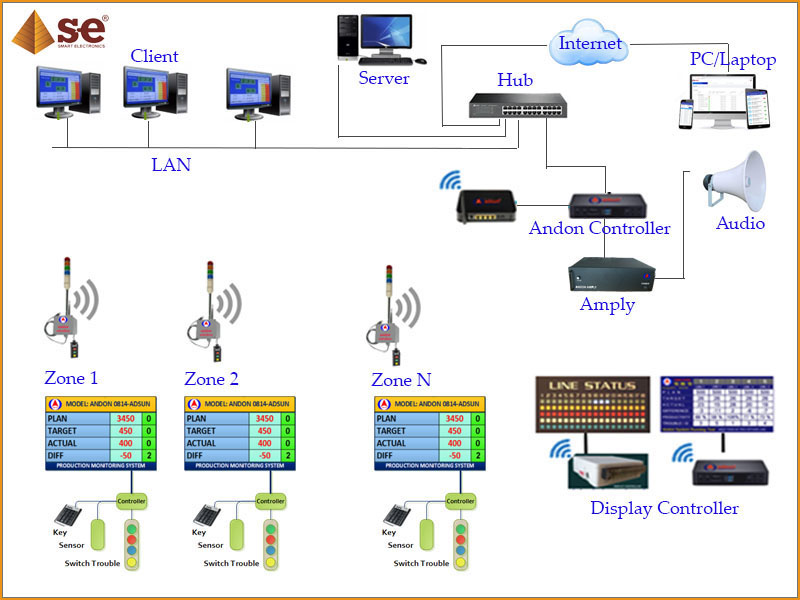

MODEL OVERVIEW OF ADON ADSUN WIRELESS SYSTEM (Adon Adsun Wireless System)

The ANDON ADSUN production management system is defined as a system that helps support production management to achieve the best performance in the production management of the enterprise. With the following functions:

The ANDON processing center is the AD-WL-1024 processor. The processing place of the ANDON system receives signals from other components in the system then analyzes, synthesizes and makes decisions to process other parts.

In principle: A wireless central processing device can manage 1024 working positions (where workers activate signals on: supplies, management, maintenance …) to the center. Depending on the scale of the company’s operations – when the working value is greater than 1024, the second device will be used.

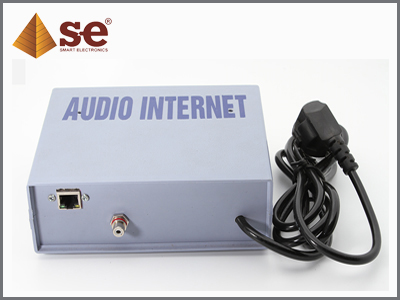

In the ANDON wireless system, the signal will be transmitted / received via RF wireless connection (receiving signals from the SUB, transmitting signals to the Audio Control Device, to computer devices through the Hub in LAN system …).

Specifications:

Product features: It is a device that receives signals from the central controller and display information on the system of terminal signs: table lamps, LCD TVs (HDMI ports), computers …

Specifications:

Product features:

Communicating with AD-WL-1024 Wireless Central Control Unit via RF..

Specifications:

Product features: AD-TLP / AD-LCD LCD Display Board (Andon Boards) is a device that displays system information, information on production status. Depending on demand of customer, information display can be displayed by: LED Display Board (lower budget), LCD TV Screen (connected via HDMI), monitor…

Specifications:

Product Features: This a device that display system information, information on production status. Depending on demand of customer, information display can be displayed by: LED Display Board (lower budget), LCD TV Screen (connected via HDMI), monitor

Specifications:

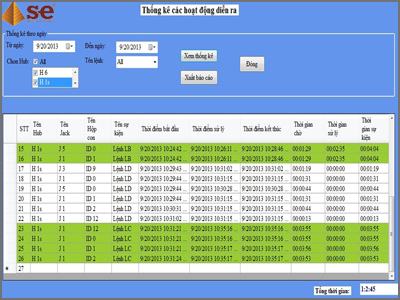

Product features: – Displaying incidents on the administration screen from time to time.

– Full statistics of events taking place by day – month – year, towards each central control unit, each group. (depending on the need of customer).

– Data of all events on the system can be exported to Excel file.

– Managing via local area network (LAN) and the Internet.

Specifications: